Understanding Battery Consumption

Battery consumption is often shown in units of mAh or Ah.

mAh = milliampere-hour

Ah = ampere-hour

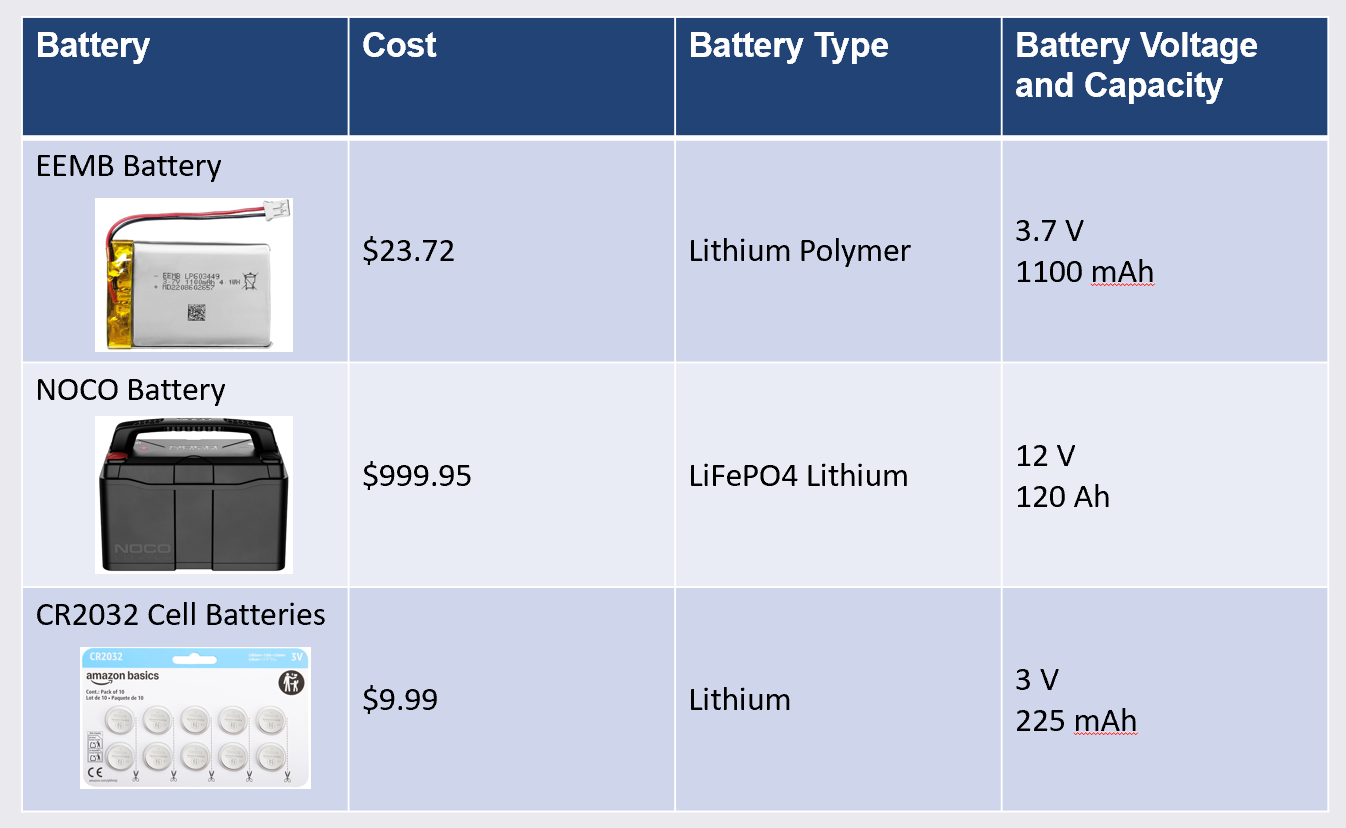

Below is a table of a few batteries I found off Amazon.

Each battery type is made for different functions. CR2032 cell batteries can be used in small electronics. The NOCO battery is rated for 12 V suitable for automotive and boating applications. Overall, the higher the cost of the battery, the greater the specifications. Of course, for specific applications especially in something as small as a fake candle, a 12 V NOCO battery is probably not the best fit for its size, cost, and voltage. Although if used, that candle might last a while since the capacity is 120 Ah, or 120,000 mAh compared to the capacity of the CR2032 cell batteries.

If you were to draw the same amount of current out of each battery, you would need 109 EEMB batteries or 533 CR2032 cell batteries to equate the same capacity of the NOCO battery.

Calculations:

Let’s assume you have a constant 1 mA current draw out of the battery indefinitely. We can calculate how long each battery will last.

EEMB: 1100 mAh / 1 mA = 1100 hours

NOCO: 120000 mAh / 1 mA = 120000 hours

CR2032: 225 mAh / 1 mA = 225 hours

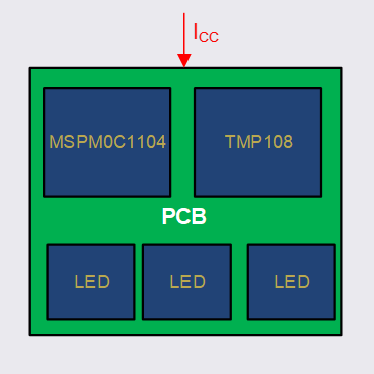

Let’s assume you have a PCB with a MSPM0C1104 micro-controller, a TMP108 temperature sensor, and 3 LED’s. Only 1 LED will glow for if the temperature is above a hot temp, at room temp, or if the temperature is too cold.

A simple PCB with MCU, temp sensor, and 3 LED’s

From each datasheet, the quiescent current, or standby mode current is assessed for each device in a DC state. I assume 1 LED is on at a single time and 1 LED draws 3 mA of current.

MSPM0C1104: ICC = 14 uA

TMP108: ICC = 6 uA

In the DC state, when no device on the PCB is actively driving a signal, the PCB consumes a total current of ICC = 3000 uA + 14 uA + 6 uA = 3020 uA or 3.02 mA.

If I were to use every device on the board at 3 V, a single CR2032 cell battery could power my PCB for approximately 225 mAh / 3.02 mA = 74.5 hours.

For a single cell battery, this is quite a long time especially since there is no circuitry on the board to disconnect the battery while the system is not in use.

Another thing to note is that this calculation of 74.5 hours of use time is calculated when the PCB is idle. This is not accounting for the brief periods of time when actions are executed from the microcontroller to read temperature data from the TMP108 over I2C. There is much more calculation needed here in the active state of the PCB. For example, MSPM0C1104 in RUN mode at a 24 MHz clock can consume 2.35 mA of current in worse case. In order to calculate how this would affect over all battery life, you would need to average the amount of time you think the MSPM0C1104 will be in RUN mode or STANDBY mode.

Let’s assume the MCU constantly runs in RUN mode consuming the max current at room temperature of 2.35 mA.

Now we have a total ICC of the PCB of…

3 mA + 2.35 mA + 6 uA = 5.356 mA

225 mAh / 5.356 mA = 42 hours

By constantly running the MCU in RUN mode, I have shorten my PCB use time by over 56%.

This small application can apply to several use cases:

Electric tooth brush - how long can you use before you have to charge (or replace the batteries)

Electric Car - How long can the car operate off its lithium ion battery pack given the current load from its electric motors? What happens to your battery consumption when you drive the car like you stole it?

Portable Phone Battery Pack - How long can the battery pack charge your phone for given its capacity and voltage?

There are many more battery applications that could be thought of, but I wanted to include a few to brainstorm typical use case for battery consumption metrics.